The global market for Wood-Plastic Composite (WPC) wall panels is experiencing robust growth, driven by the construction industry's increasing demand for durable, low-maintenance, and sustainable building materials. At the center of this expansion is the modern WPC wall panel factory, which has evolved from a niche producer into a sophisticated manufacturing hub. To succeed, these factories must navigate a competitive global landscape, leverage the inherent advantages of their product, and continuously innovate in their production processes. The global WPC market, which includes decking, fencing, and wall panels, is projected to continue expanding at a healthy rate, reflecting its growing acceptance as a mainstream cladding and interior solution.

How Is the Industry Landscape Shaping the Market?

The industry landscape for WPC wall panels is characterized by both established regional players and a globally connected supply chain, with a particularly strong manufacturing base in the Asia-Pacific region. This concentration allows for economies of scale and efficient export of WPC wall panel products worldwide. The market is fragmented, with numerous factories competing on price, quality, and design capabilities. Demand is fueled by several key sectors: residential construction and renovation, commercial projects seeking durable interior finishes, and the hospitality industry. A significant driver is the replacement market for traditional wood or vinyl siding, where the long-term value proposition of WPC wall panels is compelling. While the market shows strong potential, factories face challenges such as volatility in the cost of raw polymers and the need to continuously educate builders and consumers on the benefits of WPC technology to gain wider adoption.

What Are the Core Product Advantages Driving Demand?

The success of the WPC wall panel factory is fundamentally built on the predominant performance characteristics of its product compared to traditional materials. WPC wall panels are engineered to resist moisture, rotting, and insect damage, which are common failure points for natural wood. This makes them an ideal choice for both exterior cladding and interior wet areas like bathrooms and kitchens. They require minimal maintenance, eliminating the need for periodic painting, staining, or sealing. Furthermore, WPC wall panels offer excellent dimensional stability, resisting warping and cracking in diverse climatic conditions, which enhances their longevity and reduces callbacks for installers. From a sustainability perspective, many WPC wall panels are produced using recycled wood fibers and plastics, contributing to a circular economy and appealing to environmentally conscious specifiers and homeowners, which supports premium positioning in the market.

How Does Technological Innovation Power the Modern Factory?

To produce these high-performance panels competitively, the WPC wall panel factory relies on advanced technological innovation throughout the manufacturing process. The core begins with precise material compounding, where wood flour, polymers, and additives are mixed to create a homogeneous composite with specific properties. State-of-the-art extrusion lines are then used to shape this composite into panels. A key innovation is co-extrusion technology, where a protective polymer cap layer is applied during manufacturing, significantly enhancing the panel's resistance to UV fading and surface wear. Modern factories also utilize advanced embossing and printing techniques to create realistic wood-grain textures and a wide variety of colors, moving far beyond early generic appearances. Automation is critical for consistency and scale, with automated cutting, stacking, and packaging lines ensuring efficient throughput and maintaining tight quality control from raw material to finished WPC wall panel ready for shipment.

The WPC wall panel factory operates at the intersection of market opportunity and material science. Its growth is tied to a clear value proposition of durability and low upkeep, which resonates in the global construction market. By mastering complex extrusion and finishing technologies and optimizing production for scale and quality, these factories are poised to capture a larger share of the cladding and interior finishes market. As innovation continues to improve aesthetics and performance, the WPC wall panel is set to solidify its role as a practical and sustainable building material for the future.

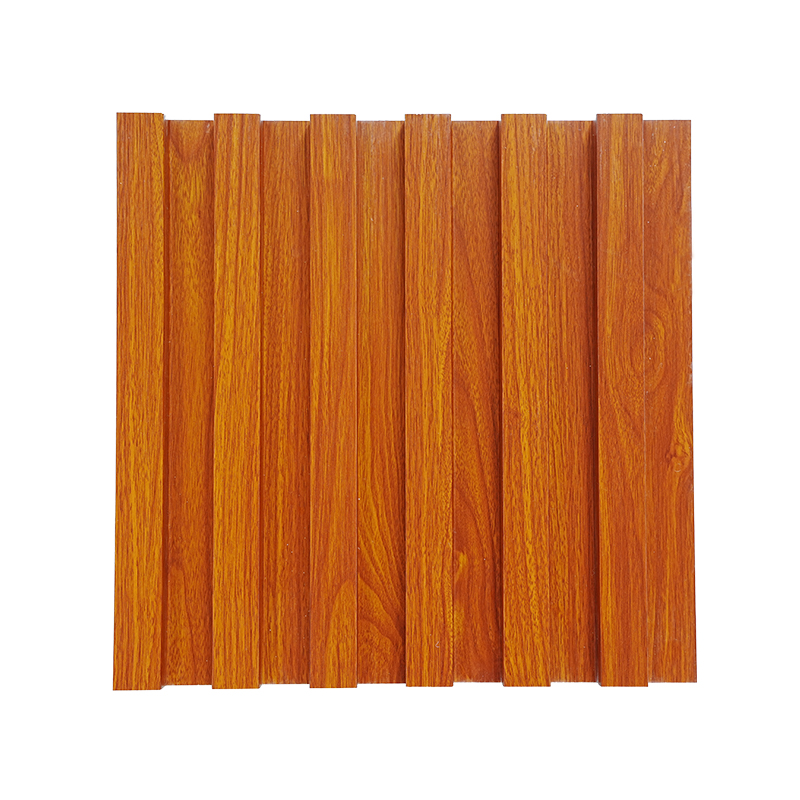

The Warm Wood-Textured WPC Panel from HAINING COMMERCE IMP& EXP CO., LTD. offers a natural aesthetic and durable solution for creating cozy interior spaces. Made from wood-plastic composite (WPC), this panel combines realistic wood-like textures with enhanced resistance to moisture, decay, and termite damage. Its lightweight yet sturdy structure allows for easy installation on walls, ceilings, or decorative partitions, while the warm surface finish adds visual comfort to residential and commercial interiors. Ideal for applications in living rooms, bedrooms, and hospitality environments, this eco-friendly panel balances sustainable design with long-lasting performance.

English

English  русский

русский  عربى

عربى